Introduction to High-Performance Concrete and Admixtures

High-performance concrete (HPC) has revolutionized modern construction. It offers superior durability, strength, and structural efficiency. Admixtures play a crucial role in achieving these properties. These chemical compounds, added in small quantities, enhance concrete performance significantly. They improve workability, accelerate or retard setting time, and increase strength. However, their effectiveness depends heavily on dosage. Incorrect dosage can lead to performance issues. This article explores how optimizing admixture dosage boosts workability and strength in HPC.

- Understanding the Role of Admixtures in HPC

1.1 Common Types of Admixtures

Concrete admixtures include several categories. Plasticizers and superplasticizers are widely used. They reduce water demand by dispersing cement particles. This improves workability without compromising strength. Air-entraining admixtures introduce tiny air bubbles. These enhance resistance to freezing and thawing. Accelerators speed up the hydration process. They are useful for cold-weather concreting. Retarders slow down setting time, beneficial for large pours. Each type affects concrete properties differently, depending on dosage.

1.2 The Balance Between Dosage and Performance

Admixtures have an optimal dosage range. Below this range, their effects are minimal. Workability may not improve, or strength gains could be insufficient. Above the optimal range, problems arise. Excessive superplasticizer can cause segregation or bleeding. Too much accelerator might lead to rapid drying and cracking. Thus, precise dosage is essential. It ensures desired properties while avoiding negative side effects.

- Impact of Admixture Dosage on Workability

2.1 Workability Definition and Measurement

Workability refers to how easily concrete can be mixed, placed, and compacted. It is measured using tests like the slump test or flow table test. Adequate workability is vital for construction efficiency. It ensures proper filling of formworks and reduces labor costs. Admixtures directly influence workability by altering the cement-water paste behavior.

2.2 Dose-Response Relationship for Workability

Superplasticizers, for example, show a linear effect up to a certain dose. Initially, increasing dosage improves flowability by dispersing particles. But beyond the saturation point, additional admixture does not enhance workability. Instead, it may cause flocculation or increased water absorption. This reduces flow and makes the mix harder to handle. Contractors must avoid over-dosage to maintain consistent workability.

2.3 Practical Considerations for Workability Optimization

Site conditions affect admixture efficiency. High temperatures can accelerate hydration, reducing effective work time. In such cases, a slight increase in retarder dosage might be necessary. Aggregate properties also matter. Rough or porous aggregates may require higher plasticizer doses to achieve desired flow. Regular testing during batching ensures dosage adjustments for varying material properties.

- Influence of Admixture Dosage on Mechanical Strength

3.1 Early and Long-Term Strength Development

Admixtures impact both early and long-term strength. Accelerators, like calcium chloride, boost early strength by speeding up hydration. However, excessive use can corrode steel reinforcement. Superplasticizers reduce water-cement ratio, leading to higher long-term strength. But too much can delay setting, affecting early strength gain. Balancing dosage is key to meeting project-specific strength requirements.

3.2 Microstructural Effects of Dosage Control

Optimal admixture dosage leads to a denser microstructure. Reduced water content means fewer capillary pores. This enhances compressive strength and durability. In contrast, under-dosage may result in a porous structure. Over-dosage can cause admixture segregation, creating weak zones. Microscopic analysis, such as SEM imaging, helps correlate dosage with microstructural quality.

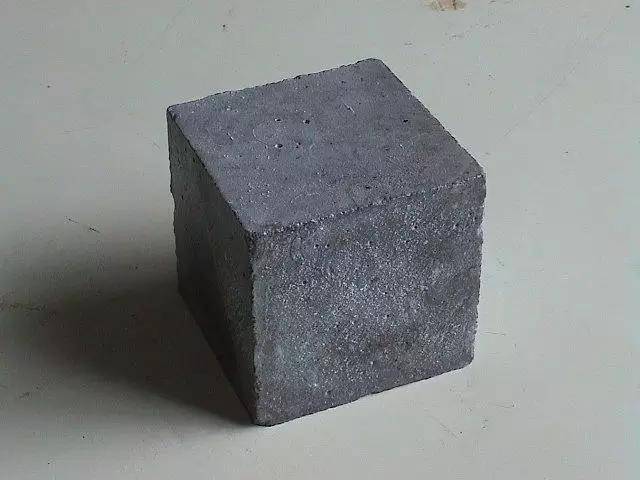

3.3 Strength Testing and Quality Assurance

Standard tests like compressive strength tests at 7 and 28 days are essential. These tests validate admixture dosage effectiveness. Engineers should conduct mix design trials with varying dosages. They can identify the dosage that maximizes strength within workability limits. Quality control protocols must include regular dosage checks to maintain consistency.

- Methods for Optimizing Admixture Dosage

4.1 Experimental Design in Mix Proportioning

Design of Experiments (DoE) is a powerful tool. It involves varying admixture dosage and other factors systematically. Researchers can analyze interactions between variables. For example, a DoE study might test superplasticizer dosage against water-cement ratio. This identifies the combination that yields optimal workability and strength. Statistical analysis helps interpret results and derive optimal dosages.

4.2 Numerical Models and Machine Learning

Advanced modeling techniques predict admixture effects. Computational fluid dynamics (CFD) simulates particle dispersion with different dosages. Machine learning algorithms analyze large datasets from previous mixes. They can predict strength and workability based on dosage and material properties. These tools reduce reliance on trial-and-error, saving time and resources.

4.3 Real-Time Monitoring During Batching

Modern batching plants use automated systems. These monitor admixture injection rates in real time. Sensors detect deviations from the target dosage. Immediate adjustments prevent under or over-dosage. Combined with slump or strength sensors, this creates a closed-loop control system. It ensures every batch meets performance specifications. - Case Studies: Successful Dosage Optimization in Projects

5.1 High-Rise Construction in Urban Areas

A recent skyscraper project in Dubai faced challenges. High ambient temperatures and complex formworks required high workability. Initial mixes with standard superplasticizer dosage showed rapid slump loss. Engineers increased dosage by 15% and added a minor retarder. This improved workability retention without delaying strength gain. The adjusted mix met both placement ease and 28-day strength requirements.

5.2 Marine Infrastructure with Durability Demands

A coastal bridge project needed concrete resistant to chloride ingress. Air-entraining admixtures were used to improve freeze-thaw resistance. Initial dosage was too low, leading to insufficient air voids. Testing revealed higher dosage created a uniform air bubble distribution. This enhanced durability while maintaining required compressive strength. The optimized dosage ensured the structure’s long-term performance in a harsh environment.

5.3 Precast Concrete Elements for Prefabrication

Prefabrication plants require high early strength for fast form turnover. Accelerator dosage was initially too high, causing thermal cracking. Reducing dosage by 10% and adding a small amount of plasticizer balanced early strength and workability. The adjusted mix allowed timely demolding without compromising long-term strength. This improved production efficiency and product quality.

- Challenges and Considerations in Dosage Optimization

6.1 Material Variability and Batch Consistency

Natural variations in cement fineness or aggregate moisture affect admixture efficiency. Cement from different batches may react differently to the same dosage. Contractors must perform regular material characterization. Adjusting dosage based on real-time material properties ensures consistent performance.

6.2 Cost-Benefit Analysis of Admixture Use

While higher dosages may improve performance, they also increase costs. Engineers must balance performance gains with budget constraints. For example, a slight reduction in workability might be acceptable if it cuts admixture costs significantly. Life-cycle cost analysis helps justify dosage choices based on long-term durability and maintenance savings.

6.3 Environmental and Regulatory Factors

Some admixtures contain chemicals regulated by environmental standards. Excessive use may lead to regulatory non-compliance. For instance, calcium chloride accelerators are banned in some regions due to steel corrosion risks. Engineers must choose eco-friendly admixtures and ensure dosages stay within allowable limits. - Future Directions in Admixture Dosage Optimization

Research is ongoing to develop smarter admixtures. Nanotechnology-based admixtures could offer precise control over hydration. Self-adjusting admixtures, responsive to environmental conditions, are on the horizon. Combined with IoT-enabled monitoring systems, these innovations will further refine dosage optimization. Future practices may rely less on manual adjustments and more on automated, data-driven solutions.

نتیجہ

Optimizing admixture dosage is critical for achieving high workability and strength in HPC. It requires understanding admixture types, their dose-response relationships, and real-world project variables. Through experimental design, advanced modeling, and real-time monitoring, engineers can fine-tune dosages to meet specific needs. Case studies demonstrate the tangible benefits of such optimization in various construction scenarios. While challenges like material variability and costs exist, ongoing research and technological advancements promise more efficient solutions. By prioritizing dosage optimization, the construction industry can unlock the full potential of HPC, driving innovation and sustainability in infrastructure development.

In summary, every project’s success hinges on careful admixture management. Balancing workability and strength through precise dosage ensures not only immediate construction efficiency but also long-term structural integrity. As the demand for HPC grows, mastering dosage optimization will remain a key factor in delivering high-quality, durable concrete structures.

ہماری پیشہ ورانہ تکنیکی ٹیم 24/7 دستیاب ہے تاکہ ہماری پروڈکٹس استعمال کرتے وقت آپ کو درپیش کسی بھی مسئلے کو حل کیا جا سکے۔ ہم آپ کے تعاون کے منتظر ہیں!